Ceramic Nozzle

Ceramic Nozzle

In FDM (Fused Deposition Modelling), an object is built by selectively depositing melted material in a

pre-determined path layer-by-layer. The materials used are thermoplastic polymers andare supplied in a filament form. FDM is the most widely used 3D Printing technology. The increasing popularity of filled or specific filaments creates a need for more wear resistant FDM nozzles. Current brass nozzles are wearing out too quickly creating an unstable 3D printing process.

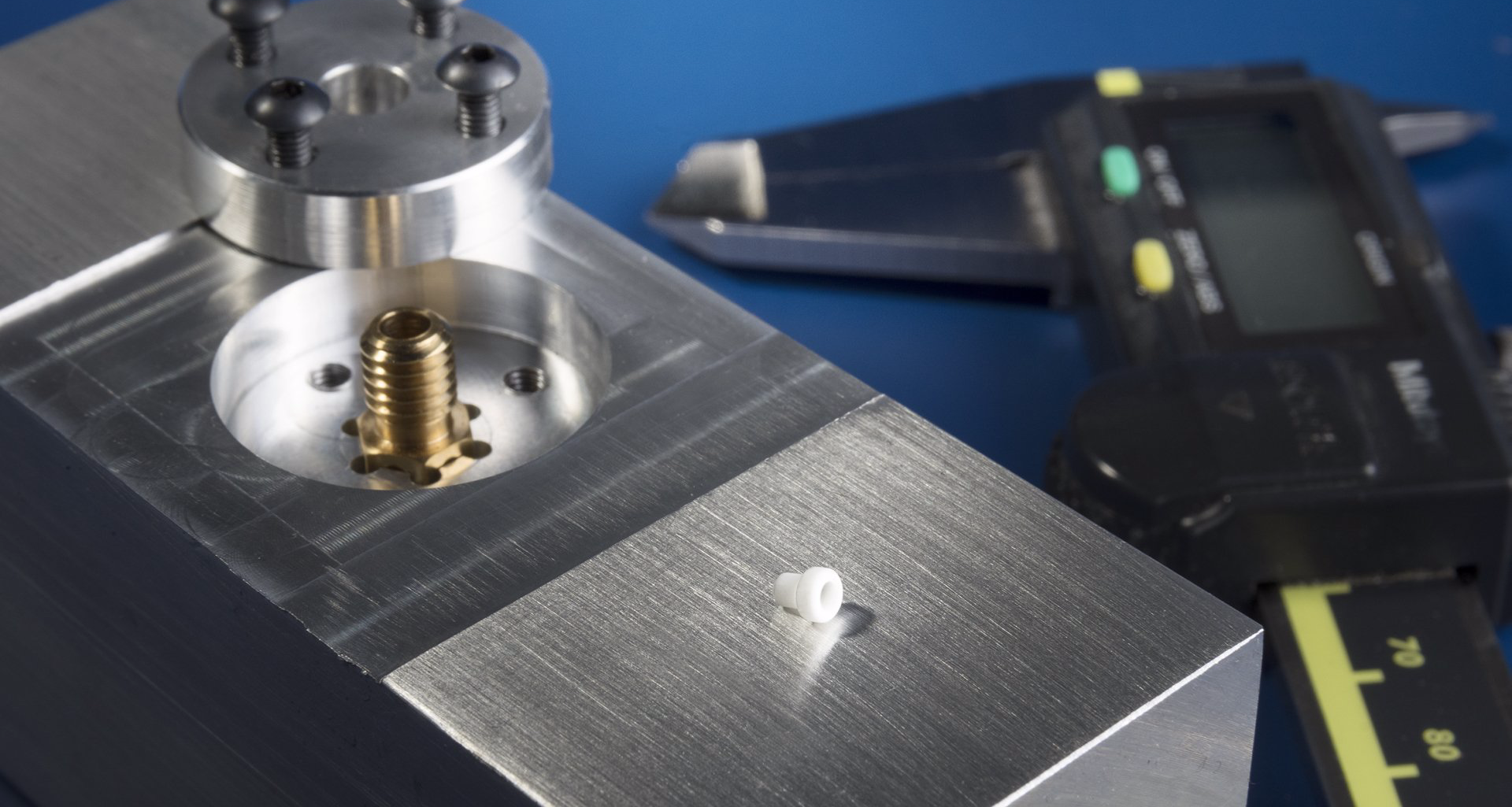

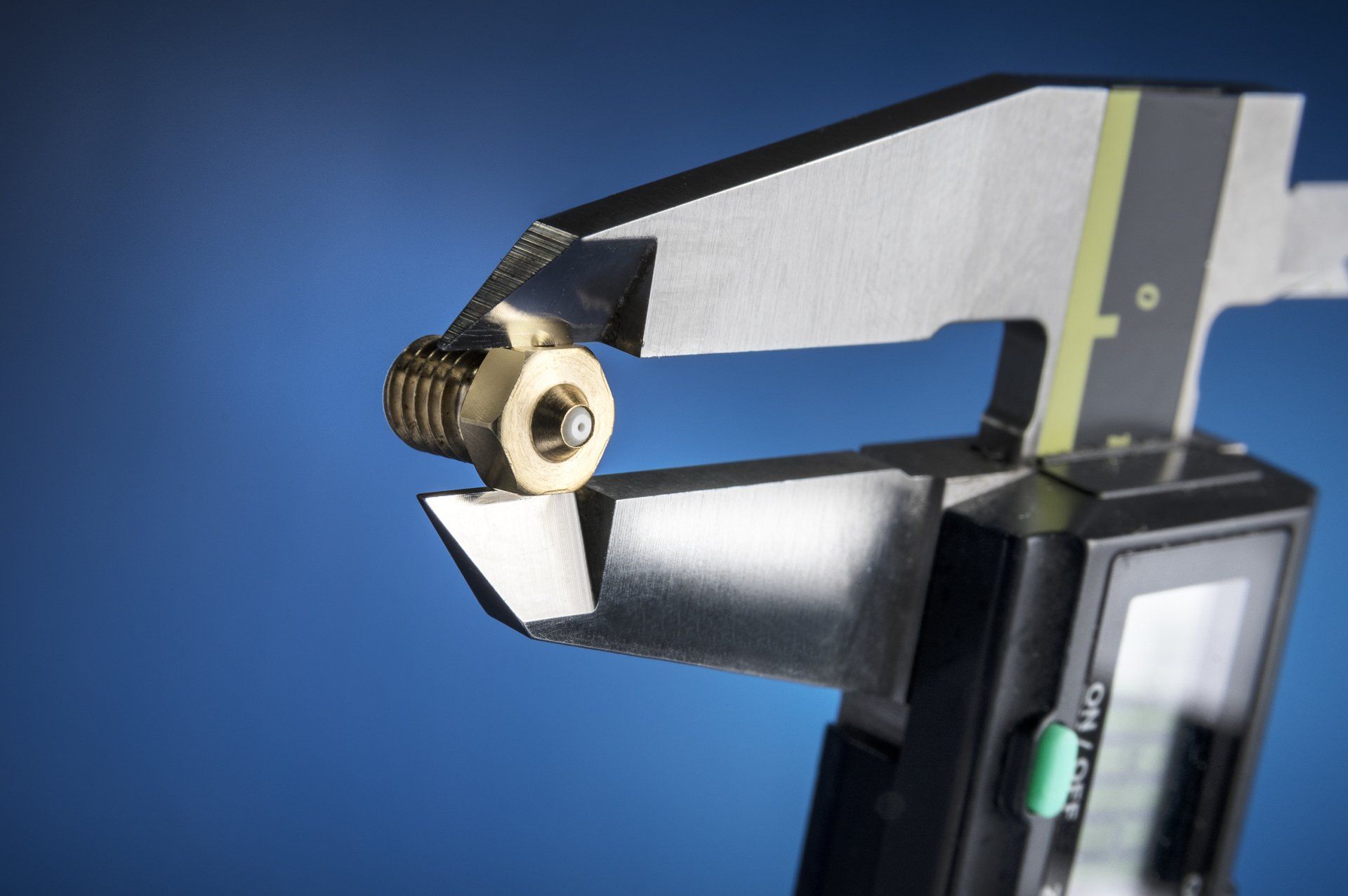

Antech Solutions guided a start-up company that wants to bring high wear resistance (ceramic) FDM nozzles for 3D printing systems to the market.

To create the first series of high wear resistance nozzles Antech Solutions build a setup to modify and assemble standard brass nozzles with ceramic inserts. High accuracy was important for the alignment and heat transfer between the brass and ceramic component.